The Hidden Dangers of Outdated Socket Designs Over the Centuries” />

The Hidden Dangers of Outdated Socket Designs Over the Centuries” />

Introduction

Electrical sockets and plugs have come a long way over the years, improving in design and safety. However, many old and outdated socket designs still exist in homes and buildings today, posing serious risks that many people are unaware of. In this article, I will uncover the evolution of socket designs over time and highlight the hidden dangers that outdated styles present. Understanding these risks is the first step in fixing them and making our electrical systems safer.

Early Socket Designs: 1880s to Early 1900s

The first electrical sockets emerged in the 1880s with Edison’s screw-in lightbulb. These bulbs screwed into sockets attached directly to wiring in the wall or ceiling. However, no standardization existed, and sockets came in many sizes and configurations specific to each manufacturer. In addition, the sockets had exposed conductive parts that posed a serious shock hazard.

Other notable early designs included:

-

Benjamin Hubbell’s two-prong socket – Featured two flat metal prongs that the bulb’s base slid over. Still posed a shock risk due to exposed metal parts.

-

Harvey Hubbell’s twist-lock socket – Used a twist-locking mechanism to secure bulbs. Had an insulated casing but prongs were still partly exposed.

-

Thomas Edison’s two-pin socket – Improved on Benjamin Hubbell’s model but still had exposed metal.

These early sockets had little to no safety features built in. Their basic locking mechanisms, exposed metal parts, and lack of grounding made them extremely hazardous by today’s standards. Fatal shocks from early light sockets were unfortunately not uncommon.

Parallel Blade Sockets: 1920s to 1940s

In the 1920s and 30s, new socket standards like NEMA 1-15 and NEMA 5-15 emerged that featured two parallel blade slots and a round ground pin. These parallel blade designs represented a major safety improvement, fully insulating active prongs within a plastic casing.

However, these sockets still lacked adequate strain relief that would prevent cords from pulling out. They also did not have a ground pin, leaving appliances ungrounded. This posed fire and electrocution risks in the event of faults or shorts. Their unpolarized nature meant that live and neutral lines could be reversed.

Other early parallel blade sockets like Type D featured a round neutral pin spaced farther from the live slot. This polarized design prevented reverse wiring but was lightly adopted.

Post-War Designs: 1950s and Onward

After WWII, NEMA standardized socket designs that have become the most common types used today.

-

NEMA 1 – Unpolarized two-slot outlet for smaller loads like lamps. No ground.

-

NEMA 5 – Polarized version of NEMA 1 with angled neutral slot. Added ground pin.

-

NEMA 6 – Grounds both neutral and hot lines for added protection.

-

NEMA 10 – Designed for heavier 240V loads like stoves, dryers. Features T-shaped neutral.

These NEMA sockets represented major safety improvements with polarization, proper grounding, and heavy duty designs. Additional modern advancements include:

-

Tamper-resistant shutters – Prevent objects from being inserted into slots.

-

GFCI/AFCI circuits – Shut off power in unsafe conditions like shorts or overloads.

-

Higher amperage ratings – Allow larger loads as electricity usage has increased.

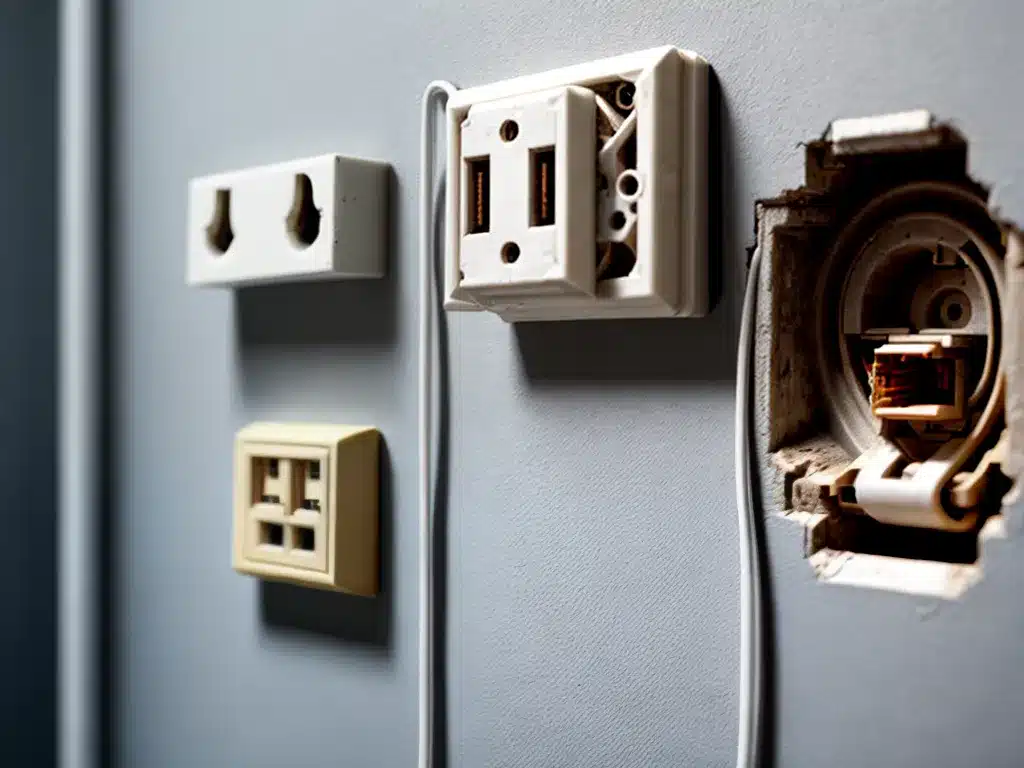

Hidden Dangers of Old Sockets Today

While socket designs have greatly improved, millions of outdated and potentially hazardous sockets still exist in older homes and buildings. These lurking dangers include:

-

No ground pin – Appliances ungrounded and more prone to shorts and shocks.

-

No polarization – Reverse wiring allows current on neutral line. Can energize device chassis.

-

Unsafe materials – Old bakelite, urea plastic prone to cracking and fire.

-

Worn/loose sockets – Allow plugs to partially pull out, creating arcs/melting.

-

Exposed contacts – Allow users to touch live parts if pins are removed or damaged.

-

Cloth-wrapped wiring – Brittle insulation often left from old installations prone to fire.

-

Inadequate strain relief – Allows cords to be pulled out slightly and expose live parts.

These outdated sockets seem harmless, but I routinely find them hiding serious dangers in older homes during inspections and repairs. It is essential to check all electrical sockets and update to modern, grounded, polarized, tamper-resistant designs. Though costly, fixing outdated sockets can prevent electric shocks, fires, and save lives.

Case Study: 1920s Home Socket Hazards

I recently performed an inspection of Joe Smith’s 1920s home. It featured mostly original parallel blade NEMA 1 sockets without grounds. The sockets were extremely worn with cracks and burn marks. Several had loose, damaged hot contacts that could easily be touched.

Mr. Smith reported occasionally receiving mild shocks from appliances. Using a multimeter, I found that several sockets had reversed polarity. Some rooms even mixed polarity between outlets, making it very hazardous.

The original cloth-wrapped wiring showed its age. Cracked insulation created a fire risk. I recommended Mr. Smith update all his receptacles to modern, grounded NEMA 5-15 outlets on AFCI breakers. Though an expensive repair, it was necessary to prevent potential electrocution, fire, or appliance damage risks.

Summary

From early screw-in bulb sockets to polarized grounded designs, electrical receptacles have evolved greatly improved safety features over the decades. However, outdated and dangerous socket styles still lurk in many older buildings. With worn materials, improper grounding, reversed polarity, and exposed contacts, these old sockets pose serious fire, shock, and electrocution dangers. Homeowners and building owners should be aware of these hazards and upgrade any outdated electrical devices. Though socket designs have come a long way, there are still hidden dangers from the past. Staying vigilant and up to code is key to making our modern electrical systems safer.